- Home

- PRODUCTS

- Hooks & Accessories

- Hooks

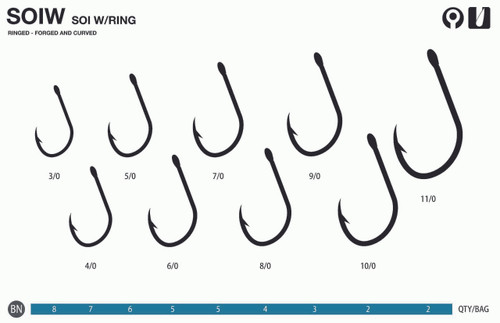

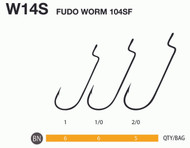

- FUDO BOX OF HOOKS JAPAN FUDO SOI W/RING 3401BN n°3/0 - 11/0

Current Top Sellers

FUDO BOX OF HOOKS JAPAN FUDO SOI W/RING 3401BN n°3/0 - 11/0

Product Description

JAPANESE TECHNOLOGICAL PERFECTION

FUDO HOOKS are the perfect quality hooks made in Japan with optimum composing of the best materials, the best technology and the highest human skills. The main characteristics of FUOO HOOKS are

1. Optimal shape - from a view point of the highest catch ability

2. Extreme sharpness, which is kept when fishing

3. Great elasticity that allows them to resist deformation.

4. Total corrosion resistance production process takes an advantage of several patents in field of metallurgy and production technique.

Special selected material - carbon steel of controlled carbon content - Is used in FUDO HOOKS production. That material, in form of calibrated wires, is prepared for FUDO engineering exclusively. There are two different sharpening methods used: mechanical and chemical. During sharpening, the level of sharpness is controlled on-line what finally brings an ideal repeatability of hook point. Hardening is realized insolated ovens where the system of computer assistance controlling the temperature with

accuracy of 0.01 degree of centigrade, and the time of treating is adjusted with accuracy of 0.001 second. In result, FUDO HOOKS are perfectly hardened and achieve excellent power and elasticity. All models of FUDO HOOKS have" Built-In "corrosion resistance.

FUDO DELTA FAMILY

Modem hooks with especially designed, completely new, shape of point. Special gouge at the flat keeps fishing line in right space.

Profile of new point has triangle shape with edges and elongated point so now it looks like ending of harpoon tooth.

FUDO HOOKS , HIGH CARBON STEEL , SOI W/RING 3401BN n°3/0 - 11/0

FUDO HOOKS , HIGH CARBON STEEL , SOI W/RING 3401BN n°3/0 - 11/0 Special selected material - carbon steel of controlled carbon content - Is used in FUDO HOOKS production. That material, in form of calibrated wires, is prepared for FUDO engineering exclusively. There are two different sharpening methods used: mechanical and chemical. During sharpening, the level of sharpness is controlled on-line what finally brings an ideal repeatability of hook point. Hardening is realized insolated ovens where the system of computer assistance controlling the temperature with

accuracy of 0.01 degree of centigrade, and the time of treating is adjusted with accuracy of 0.001 second. In result, FUDO HOOKS are perfectly hardened and achieve excellent power and elasticity. All models of FUDO HOOKS have" Built-In "corrosion resistance.

FUDO DELTA FAMILY

Loading... Please wait...

Loading... Please wait...